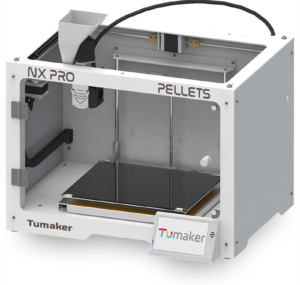

Tumaker Professional and Large Format Pellet Fed 3D Printers

Tumaker 3D Printers are high-performance, robust professional printers custom made for every order! They are used by you the innovator to expand your 3D printing capabilities and support your custom material development!

High quality, entry level professional and large format printers

Rapidly elevate your R&D capabilities throughout all levels of your additive manufacturing journey

Capable of printing a wide range of unique materials

From commodity plastics, biopolymers, ceramics and engineered resins with or without fillers, your material possibilities our endless!

Independent dual extruders (IDEX) available in pellet and filament combinations

Customize your Tumaker printer with up to five pellet-filmament combinations

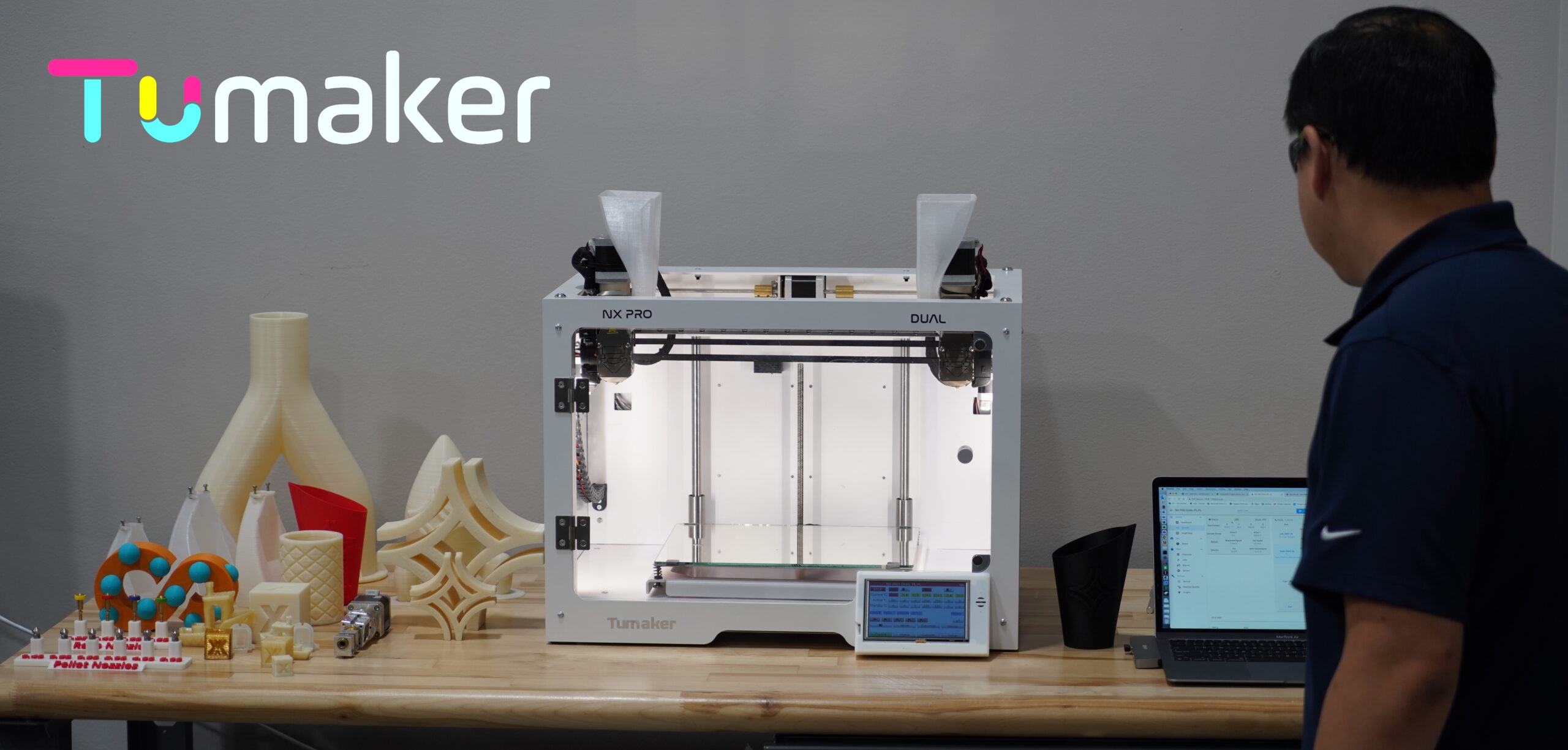

Featured Professional and Desktop 3D printers

Tumaker BIGFoot

Pro Pellets 500

Tumaker Extrusion Systems

Tumaker answers different manufacturing needs by offering 5 different extrusion systems for its NX Pro and Bigfoot printers:

- Single Direct Drive HR extrusion for filament.

- Single extrusion for pellets.

- Dual Direct Drive HR extrusion for filament.

- Dual extrusion for pellets.

- Dual Direct Drive HR extrusion for filament and pellets.

The NX Pro and Bigfoot printers are capable of working with virtually all materials developed for 3D printing, be it in filament or pellet format. The materials compatible with each extrusion system as well as the maximum extrusion and bed temperatures are listed in the table below:

| Extrusion configuration | Maximum extrusion temperature | Maximum bed temperature | Compatible materials |

| Single/Dual Direct Drive HR extrusion for filament | 350 ºC | 100 ºC | Aquasys® Support Materials, Caverna™ Build Materials, Entropic™ Sustainable Materials, Recycled, PLA Crystal, PLA Silk, PLA 3D870, PLA 3D850, ASA, ABS, ABS FP, r-PET, PET CF, PETG, PETG FP, PETG MDT, PVA, PVA Ultra, HIPS, PC, PP, PP Support, PP GF, PA CF, Nylstrong, PA HT, FLEX 93A, FLEX 98A, TPU Hardness+, TPU CF, Glace (PVB), Medical |

| Single/dual extrusion for pellets | 350 ºC | 100 ºC | Aquasys® Support Materials, Caverna™ Build Materials, Entropic™ Sustainable Materials, ABS, Catamold 316L, PA6 30GF, PLA, PCL, ASA, PETG, PC+PBT, PC, LDPE, PEKK, PP, PP 30CF, SEBS, Soft TPU Sh18A, PEI Ultem, Ceramic Al2O3, PVC, ABS CF, FLEXA 93, Wood, PA16F + Ferrite, PA12 + Neodymium, PP + Mineral filler, Grilon BK30, PPC 7712, SAN, PC/ASA, PC 20CF, PA66 30GF |

| Dual extrusion for filament + pellets | 350 ºC | 100 ºC | Same as above |

We’re Here to Help

Please reach out to Chelsey Strenke - Your Tumaker Expert

I love to be challenged mentally and to expand my personal boundaries through new experiences. I currently have deep experiences in additive manufacturing, plastics extrusion, analytical/quality chemistry, technical writing, B2B sales, product launches and project management.

How can we help you? (Check all that apply.)