Capabilities

Interfacial’s Development Services Division is located in the Cervenka Center, a world-class incubation facility in Prescott, Wisconsin. Its labs are outfitted with state of the art melt processing, prototyping and characterization equipment.

Melt Processing Capabilities

- 11 mm Thermo Fisher Twin Screw Extruder (40:1 L:D)

- 27 mm Entek Twin Screw Extruder (52:1 L:D)

- Twin Screw Extruder auxiliaries

- Side stuffing

- Gravimetric feeding

- Liquid injection unit

- Melt pump

- Vacuum stuffer

- Inline screen changer

- Profile extrusion

- Air/water cooling belt

- Strand and underwater pelletizing

- High speed blender

- Inline rheometer

- Thermo Fisher Mini-molder

- Arburg 270C 40 Ton Injection Molder

- ASTM Specimen and Plaque tooling

- Pellet Mill

Characterization Capabilities

- Hitachi SEM/EDAX

- Netsch TGA/DSC

- Bruker FTIR

- Waters GPC/HPLC

- MTS Universal Testing Machine

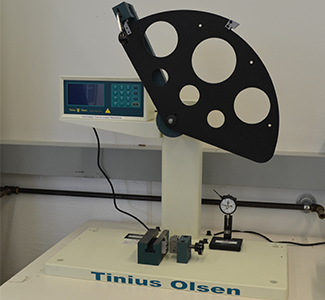

- Tinius Olsen Impact Tester

- RayRan Heat Distortion Temperature Tester

- RayRan Melt Flow Indexer

- Dynisco Capillary Rheometer

- Moisture Analyzer

- Conductivity Tester

- Durometer Tester

- Colorimeter

- Sintering Furnace

- Drying Ovens

Chemical Synthesis Capabilities

- Organic/Inorganic Synthesis

- Glassware

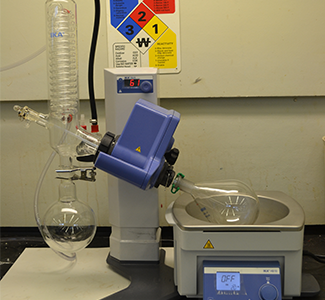

- Roto-evaporators

- Precision Balances

- Silverson High Speed Mixer

Additive Manufacturing

(3D Printing)

- Unique Industry Knowledge Related to 3D Printing Materials and Processing Technologies

- Novel Materials Development Capability for Open and Closed 3D Printing Systems.

- Prototyping and Short Run Manufacturing based on the Arburg Freeformer Technology.

- Ability to Work with Novel 3D Printed Materials, including FDA Approved Materials, Polyolefins, etc.

- Applications Development Utilizing Freeformer Technology and Novel Materials.